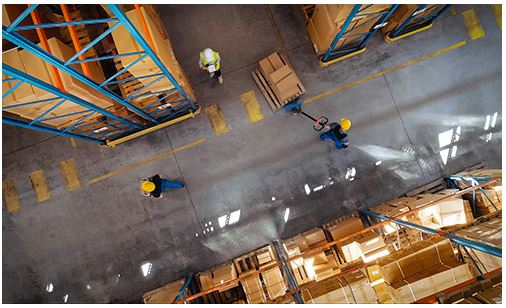

So often when we talk about the supply chain, we dissect the manufacturing process, looking to optimize each step without thinking about the space in which it will occur. Optimizing warehouse layouts “is an essential part of driving efficiency and reducing costs. Having a layout that enables goods to move in and out swiftly is important because it creates an efficient lean-warehousing system and helps customers receive their goods sooner.”

Our partners at BarTender, share some of the impacts that optimized or unoptimized warehouse layouts can have in the following overview:

- The direct impact on productivity and therefore profitability.

- How warehouse layout contributes to staff safety and protecting goods from damage and spoilage.

- A well-planned warehouse is essential for the speedy deliveries demanded by consumers.

- The importance of labeling in managing a productive warehouse.

Productivity

“Warehouse layout directly impacts staff productivity. Within a warehouse operation, workers typically account for 60-65% of the total operating budget.” This makes it even more important to have a layout that ensures staff efficiently move through the warehouse.

Safety

Warehouse layout impacts safety, not only when it comes to sufficient space for equipment but also in goods storage like hazardous materials.

Damage and waste

Unoptimized layouts “contribute to damage and loss of goods,” leading to unnecessary expenses. For example, if goods aren’t rotated and shipped on time by their expiration date they must be discarded, or improperly stored items can be cross-contaminated or spoiled.

Expansion

Utilizing existing space without moving or expanding into a new facility enables a business to minimize operational budget impact.

Delivery speed

An optimized warehouse layout ensures that staff can fulfill orders quickly and efficiently, getting orders to customers faster and more accurately.

Labeling is essential at every stage of the warehouse process. It starts with manufacturer labels on raw materials and ends with consumer labels on final products, including barcode details. Pragmatyxs can help ensure your labeling system aligns seamlessly with your optimized warehouse layout.