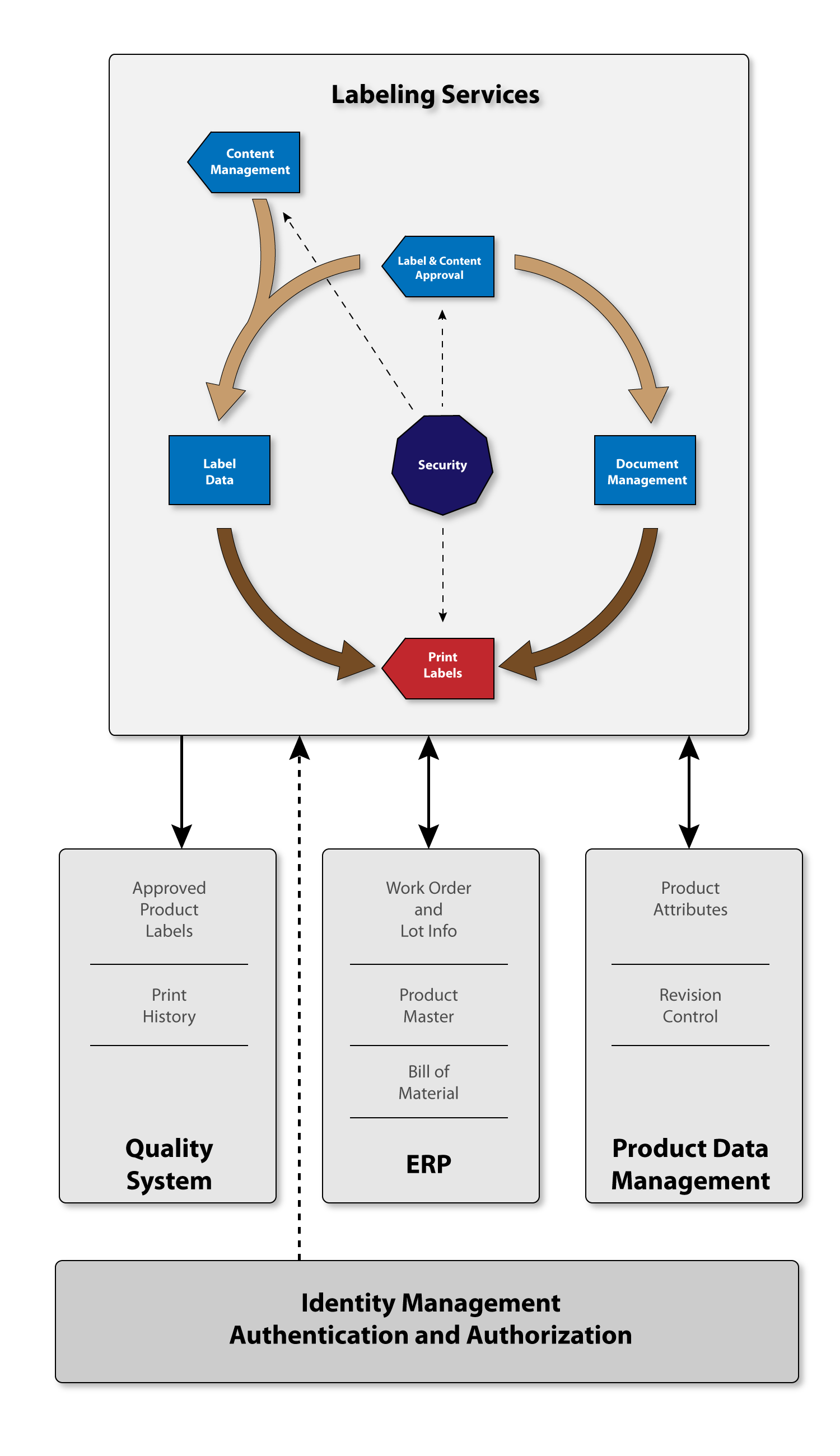

In our previous article we introduced the concept of Labeling as a Service (LaaS) as an approach to deliver reliable and scaleable product labeling to the enterprise. Today we propose guiding principles in the design of your product labeling service to minimize complexity, improve manageability and effectively utilize existing systems and data.

Our labeling service design principles include:

- Efficiently use system and infrastructure resources

- Leverage existing services and platforms

- Provide centralized monitoring and management

- Integrate, don’t replicate data and general application services

Efficient Use of Resources

In order to meet product manufacturing and distribution requirements labeling services need the ability to quickly scale to support required output volumes. Labeling processes should be “lightweight” and scale in a manner that does not negatively impact other systems or overall network performance. Approaches to consider include:

- Deployment of virtualized labeling services for load-balancing, fault tolerance and scaleability

- Forward-deployment of labeling services to remote locations to reduce network bandwidth consumption, improve local label output performance and isolate plants from outages at other locations

- Integration with externally hosted or “cloud” computing environments to provide on-demand capacity, failover and distributed services for remote locations and partners

Leverage Existing Services and Platforms

Duplicated services and infrastructure increase complexity and potentially introduce technologies that the implementation and support teams are not familiar with. Redundant environments add technical overhead and increased administration costs. Labeling services based on established standards and designed to integrate within current environments offer lower implementation and support costs and ensure data and process integrity.

Shared service opportunities include:

- User authentication and authorization services such as Microsoft Active Directory and other Identity Management or Single Sign-On solutions

- Database services including Oracle and Microsoft SQL Server

- Product, document management and workflow services – Microsoft SharePoint, EMC Documentum, Oracle Agile or PTC Windchill

- Virtualization environments – VMware vSphere, Microsoft Hyper-V

Centralized Monitoring and Management

Distributed services can offer a level of robustness, flexibility and performance not available from centralized solutions yet are difficult and costly to manage if integrated tools are not available for administration and monitoring.

A centralized management and monitoring solution should provide:

- Resource allocation, configuration and deployment of labeling services within the enterprise and to remotely hosted or “cloud” platforms

- Real-time monitoring, diagnostics and alerts

- Print history logging

- Security administration

Integration vs. Replication

Information required for product labeling is often in multiple sources including ERP, product data management and quality systems. For companies with global manufacturing and distribution locations or who ship product to international markets, instructions for use (IFU) and safety information is required to be translated or “localized” for the intended region or country. Traditional methods use a batch oriented export and transform process to replicate product data to a labeling-specific data repository. The requirement to maintain synchronization between multiple systems adds complexity, limits options to interface with other systems and can impact data integrity.

While there maybe technical justification to extract and maintain labeling data in a separate repository, an overarching design goal should strive to retrieve and transform data directly from the various source systems at print-time and minimize replication of product information. This model more clearly defines the roles of the various systems that interact within the product labeling process and more easily adapts to changing process and data requirements.

Summary

While there are many design approaches to be considered, the overall goal is a labeling service infrastructure that is robust, scaleable and cost effective. “Shrinking the Footprint” of your labeling environment results in services that are integral to your existing enterprise systems and delivered in a manner that is compliant with proven standards and compatible with your practices.

Stay tuned for future articles where we will deep dive into specific approaches to designing your enterprise labeling service.