STREAMLINE AND SIMPLIFY FOR OPTIMIZED EFFICIENCY

COMPANY OVERVIEW

An orthopedic company that has been supplying innovative medical device solutions for joint reconstruction, spinal surgery, and sports medicine for over 100 years.

THE CHALLENGE

A medical device company, specializing in orthopedics, came to us with the need to massively reduce the number of design templates in their production labeling solution. At the time, label sprawl had grown their labeling assets to about 7,000 unique design templates.

While consolidation of the number of templates without much redesign was the primary goal for this project, we discovered additional opportunities that once implemented, will result in further reductions and future-proofing of their design process.

PRAGMATYXS’ SOLUTION

Pragmatyxs analyzed the company’s labeling solution, identified the number of templates associated to different label stock sizes, and created a strategy to reduce the templates to a more manageable quantity. Pragmatyxs sample printed each template, allowing us to view each template as an image and categorize them based on common requirements and data. After the sample printing and categorization, we reviewed all template fields to ensure that once consolidated, print output would produce all fields and images.

We focused on significantly improving their template design practices, including process and procedural improvements.

After consolidation, Pragmatyxs built a catalog for the company’s label design team to reference the new consolidated templates with ease and efficiency. The solution we provided better leveraged new features available in their labeling software solution. In addition, we focused on significantly improving their template design practices, including process and procedural improvements. At Pragmatyxs we believe that the best solutions are comprehensive and encompass people, processes, data, and technology.

THE RESULTS

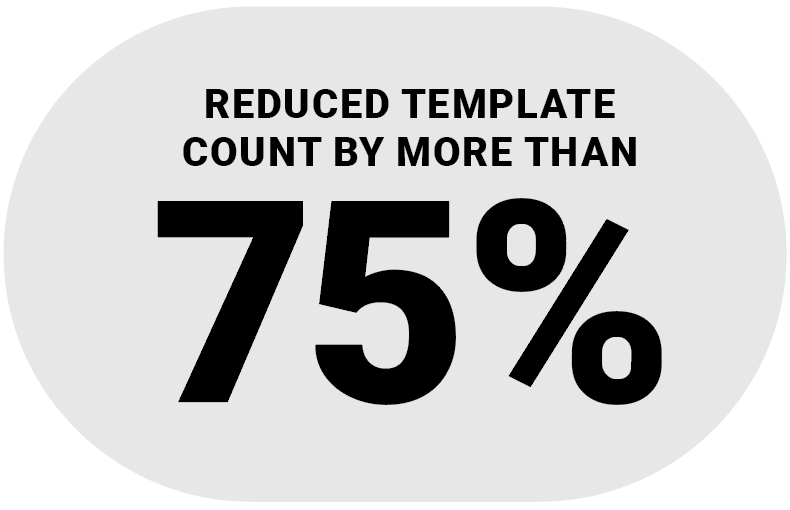

Reducing the template count by more than 75% significantly decreased the amount of time to make template modifications, create new templates, and diminished application server resource requirements. Consolidating templates to a manageable amount will help this company make future business decisions efficiently without the need to administer a cumbersome template catalog. This collaborative project has improved customer agility and decreased time to market for fulfilling their demanding product labeling needs.